Technical index of rapid temperature change (hot and humid) chamber

|

Model

|

MESS-250

|

MESS-500

|

MESS-1000

|

MESS-1500

|

|

Performance parameters

|

Temperature range

|

﹣40﹣﹢150℃(Temperature range:﹣20﹢80℃):﹣70﹢150℃(Temperature range:﹣55﹢80℃

|

|

Temperature fluctuation

|

±0.3℃±0.5℃

|

|

Temperature deviation

|

±1℃±2℃

|

|

Humidity deviation

|

±3%RH(<75%RH) ±5%RH(≦75%RH)

|

|

Heating and cooling rate

|

5/10/15/20℃/min

|

|

Standard load

|

5kg aluminum ingots

|

12kg aluminum ingots

|

25kg aluminum ingots

|

30kg aluminum ingots

|

|

Structure

|

Shell

|

High - strength cold - rolled steel plate double - sided powder baking

|

|

Inner wall

|

SUS#304 stainless steel 2B panel

|

|

Insulation Materials

|

Glass fiber + polyurethane foam

|

|

Cooling System

|

Refrigeration method

|

Single - stage mechanical refrigeration / cascade two - stage compressor refrigeration

|

|

Refrigerating machines

|

Imported compressors

|

|

Heater

|

Electric wire heater

|

|

Observation window(mm)

|

300*400

|

|

Test hole(mm)

|

On the left:One 50

|

right:One 100

|

|

Temperature Sensor

|

Platinum resistance pt100

|

|

Controller

|

Original imported from Japan 7 TFT touch screen

|

|

Recording means

|

Built-in paperless recorder function (external print)

|

|

Computer interface

|

UCB interface with machine operation

|

|

Internal dimensions(cm)

|

width

|

70

|

80

|

100

|

100

|

|

height

|

70

|

90

|

100

|

150

|

|

depth

|

50

|

70

|

100

|

100

|

|

Motor cover height

|

190

|

210

|

220

|

210

|

|

power supply

|

AV380V 50Hz Three phase wire + ground wire

|

|

Standard configuration

|

Product manual 1 copies. Test report 1, certificate and quality assurance of the 1, 2 partitions, a soft silicone rubber plug

|

|

Meet the configuration

|

GB11158\GBT2423\GC/T2423.1/T2423.2/GBT24423.2 GJB1500.3\GJB15.0

|

Process Profile

Structure technology

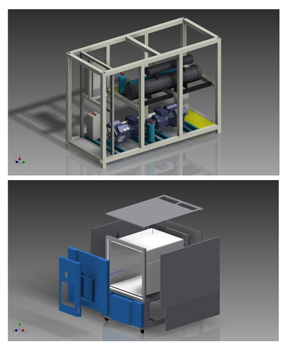

1.Company hardware equipment

Imports of German laser laser machine 1;

Title of the AMADA AIRS-255NT punching and a Taiwan;

Germany for all types of carbon dioxide welding machine and argon welding machine more than 10 Autodrsk inventor 3D graphics software, 3D sheet metal demolition and design of virtual assembly.

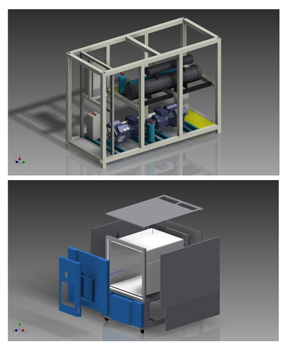

2.Shell made of high quality galvanized steel, electrostatic powder coating to be paint;

3.The inner box is made of imported SUS # 304 stainless steel, with full welding process to prevent leakage and penetration of high temperature and high humidity air inside the box; inner liner fillet design of inner box can better discharge condensate of side wall.

2.Shell made of high quality galvanized steel, electrostatic powder coating to be paint;

3.The inner box is made of imported SUS # 304 stainless steel, with full welding process to prevent leakage and penetration of high temperature and high humidity air inside the box; inner liner fillet design of inner box can better discharge condensate of side wall.

Refrigeration series of technology

1.standardization

1.1 High-quality steel pipe and welding process standardization; according to the standard tube layout to ensure stable and reliable model system;

1.2 Imports of Italian imports of pipe bending machine the whole bend, a significant reduction in solder joints and welding generated when the pipe oxide, improve system reliability!

2.Pipeline shock and support

2.1 The United States and Tyco on the support of the cooling copper pipe has strict requirements, taking into account the pipeline shock conditions in the cooling pipe to increase the arc and bending the use of special nylon clip fixed way to avoid the circular vibration and temperature changes caused by Pipe deformation and leakage, improve the reliability of the entire refrigeration system.

2.2 No oxidation welding process

As we all know, the cleanliness of the refrigeration system is directly related to the efficiency of the refrigeration system and operating life; the United States and Tyco welding operation using standardized to avoid a large number of pipe oxide pollution when welding!

Control circuit technology

1. Power distribution layout According to the technical department of the distribution assembly plans to install electrical components used internationally renowned brands: Omron, Schneider, Germany phoenix terminals, line code clearly marked.

Selection of the old domestic brand, (Zhujiang cable) to ensure that the quality of the wire; control line minimum 0.75 square RV soft copper wire, all the major load such as motor compressors are based on EC trunking safety current standard trapping trail selection!

Compressor cable box cable mouth with sealant processing, to prevent frosting junction box terminal short circuit.

All terminal screws are connected to the standard fixed torque, to ensure reliable fastening to prevent loose ignition and other hidden dangers!

Refrigeration Technology

3D refrigeration system management drawing

Variable Frequency Control Technology of Refrigeration System

In the frequency conversion refrigeration system, even if the power frequency 50HZ is fixed, can change the

frequency through the frequency changer, thus adjusts the compression rotational speed, causes the cold quantity

continuously to change, guarantees the compressor movement load in the test box the actual load to match (namely

test body temperature Increase, the compressor frequency to rise, improve the cooling capacity, on the contrary, the

compressor frequency to reduce and reduce the cooling capacity) greatly saves the unnecessary loss of operation to achieve energy-saving purposes. In the beginning of the test chamber can also run by increasing the frequency of the compressor to improve the capacity of the cooling system to achieve the purpose of rapid cooling.

The chamber adopts frequency conversion refrigeration system, which can precisely control the temperature of the box body, make the temperature of the box body constant, the temperature fluctuation is small, and the suction and discharge pressure of the refrigeration system is stable and the compressor runs stably and reliably. Electronic expansion flow servo.

Refrigeration system technology Other energy - saving technologies

A) The use of PID + PWM principle VRF technology (electronic expansion valve according to the thermal conditions of flow control)

Low-temperature working state, the heater does not participate in the work, through the PID + PWM regulation of the cooling (cooling capacity of the air flow control system); low-temperature working conditions, the use of the principle of PID PID VRF technology (refrigerant flow control) Flow rate and flow direction of the cooling pipe, cold side of the pipeline, heat the next three-way flow pipe to adjust to achieve the work of the temperature is automatically constant, this method in low temperature conditions, the studio can automatically achieve a constant temperature, Low temperature conditions, can achieve a 30% reduction in energy consumption. The technology is based on Danfoss ETS system electronic expansion valve, can be applied to different cooling capacity requirements of the cooling adjustment, both at different cooling rate requirements, to achieve the compressor cooling capacity adjustment.

B) the size of two sets of compressor design technology, according to load conditions automatically start and stop (large series is designed)

The refrigeration unit is equipped with a set of semi-hermetic compressors composed of binary cascade refrigeration system plus a full-density single-stage refrigeration system. Configure the mother; according to the load conditions inside the box and the cooling rate of intelligence to open the different compressor groups, so that the cooling capacity of the box and the compressor output power to achieve the best match, in order to achieve the best operating conditions in the compressor section circle to Extend the service life of the compressor. More importantly, a large set of traditional design compared to the energy-saving effect is very obvious, you can achieve more than 30% of the temperature control. With VRF technology)

Technical index of rapid temperature change (hot and humid) chamber

Technical index of rapid temperature change (hot and humid) chamber

Process Profile

Process Profile