Automobile integrated environmental experiment warehouse

Automobile applications in people's lives more and more widely, and the application of automotive electronics technology has almost penetrated into all the car system, China has become the world's third largest automobile producer, the world's major car manufacturers have been in the same investment and construction , Forced by cost pressures, most auto manufacturers are gradually promoting the import of zero import, which gives China's automotive electronics components manufacturing enterprise development has brought great opportunities.

Automotive electronic products environmental testing of the main test items include:

(1)Power supply environmental test

Power supply environmental tests include DC, overvoltage, superimposed AC voltage, slow rise and fall of supply voltage, supply voltage interruption, reverse voltage, open circuit test, short circuit protection, withstand voltage, insulation resistance and electromagnetic compatibility.

(2)Mechanical environmental testing

Mechanical environmental tests include sinusoidal vibration, random vibration, mechanical shock, free fall, surface dish strength / scratches and surface friction, gravel impact and so on.

(3)Climate and environment test

Climate and environmental tests include constant temperature test, temperature change test, temperature cycle test, ice water impact test, salt spray test, hot and humid cycle test, constant hot and humid test, mixed gas spill corrosion test, solar radiation test.

(4)Chemical environment test

Chemical environmental tests refer to the components and components that may contact the specified chemical reagents to resist the corrosion of these reagents.

Dongguan MENTEK Testing Equipment Co.,Ltd. as early as 2003 began the automotive electronics products, environmental testing. At present, there are large, medium and small models of comprehensive environmental testing equipment for different specifications, types, sizes and different technical requirements of automotive products to provide a variety of test equipment, including high and low temperature hot environment alternating test equipment, Waterproof IPI-IP8 grade test standards in the environmental test project requirements, over the years for a number of automotive electronics manufacturers to complete the tens of thousands of hours of integrated environmental testing, the test technology and test capabilities in the leading domestic level, can help manufacturers Identify and improve product weaknesses, providing product reliability levels.

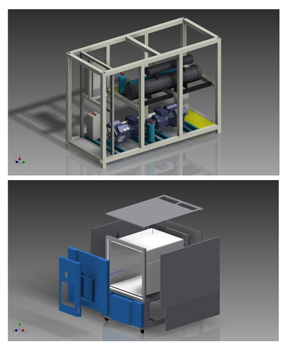

Automotive integrated environment for the car manufacturers to provide product development in the performance of the test. The test cabin is mainly composed of cabin body structure, air conditioning system, fresh air system, dynamometer system, exhaust system, solar radiation system and other components.

◆GB1835203-2005 Emission test ◆GB/T658-2000 Air conditioning test ◆ GB18233-2003 Fuel consumption test

◆GB/T12542-1990 Thermal balance test ◆GB/T12781-1991 Lubrication test of automobile oil supply system ◆GB/T12546-1990 Automotive Thermal Ventilation Test

◆GB/T12544-1991 Car heating test (air conditioning) ◆GB11555-1994 Defrost test defrost test ◆GB/T12535-1991 Low temperature start test

◆GB/T12544-1990 Maximum speed test ◆GB/T12543-1990 Accelerated test ◆GB/T12536-1990 Glide test

◆GB/T12546-1990 Minimum stable speed test

Comprehensive technical parameters of automobile integrated environment

1.Temperature control test

Temperature range: -40 ℃ -80 ℃

Temperature Accuracy: When the car is at rest. The temperature of the cabin to maintain ± 2 ℃ by the test vehicle heat load impact, can be set within the temperature control smoothly, the vehicle 0.5 m control point temperature fluctuations & lt; ± 1 ℃, the general control point temperature fluctuations & lt; ± 2 ℃. Temperature -40 ° C to 60 ° C Bulkhead non-condensing discharge test: Absolute humidity (H) 5.5 ≦ 12.2gh2o / kg Air.

Euro 3 / 4VI line test: the humidity throughout the test period should be low enough to prevent condensation on the chassis dynamometer drum.

Change temperature: to ensure no frost.

Performance test: the test chamber temperature 25 ℃, the relative temperature of 50% RH ± 5%

4.Chamber atmospheric pressure test

To ensure the stability of the test run when the cabin is slightly positive pressure (short-term negative pressure), with air pressure balance device.

Cabin Rizhao Test:

proper temperature:35-60℃

Sunshine light source: full spectrum bulb;

Installation: removable, adjustable angle (45 degrees or more)

Sunshine intensity is not less than 1200W / m2 ± 20W / m2, (from the height of the roof height of the average temperature), can be fragmented control sunshine intensity, but also the overall control; solar radiation intensity control accuracy ± 20W / m2 Roof height of the level)

5.Cabin operation test:

The system has the dual operation function of automatic control / manual control;

During the test process can be achieved automatically / manual two-way worry-free switch;

Real-time display test and test parameters; real-time curve display; real-time parameter display and print; test data real-time storage; system with test and self-diagnostic function;

6.Safety monitoring system:

The test room is divided by the pressure balance and the oxygen concentration, the exhaust gas concentration control the new wind, but also equipped with a little security measures: alarm sound prompt independent (separate from the main controller) electronic over-temperature alarm protection: mechanical over-temperature alarm protection: Over-current, overheating, overpressure, oil pressure differential protection: explosion-proof device: CO, NOX exhaust exceeded protection; power owed, wrong phase protection: water, water, wet anti-dry protection;

7.Exhaust system

Automotive Standard Emission Test

temperature range:20℃-60℃

Size: Customizable

Equipment features: equipment for installation of the ignition engine (in the future can be extended to the oil machine), the total quality of not more than 3500KG M class, N class car according to national and national conditions of the discharge regulations test, in the test can provide - 20 ℃ -45 ℃ environmental simulation conditions (engine displacement: maximum 6L: speed: 120KM / H, the test can be controlled at -20 ℃)

Remarks:

1.Temperature control range:-40℃~40℃

2.Ground load-bearing ground load:≧300kg

3.Internal net size can be customized according to user requirements

2. Test load range:

Although the vehicle size: 700 * 2200 * 2100mm, can be customized

Maximum vehicle weight: 400kg

The maximum power of the car:300kw

Vehicle maximum suction capacity: 720m3 / h, exhaust pipe outlet maximum temperature of 350 ℃

The maximum heat of the vehicle:3000kw

Drum tracking fan: power 100kw. Wind speed 260km / h, air flow 300000m3 / h

Fresh air supply: -40 ℃ -10 ℃, the fresh air volume is greater than 1000m3 / h-10 ℃ -0 ℃, the fresh air volume is greater than 2500m3 / h 0 ℃ -20 ℃, the fresh air volume is greater than 3500m3 / h 20 ℃ -30 ℃ , The fresh air volume is greater than 5000m3 / h

3.Humidity control test

Meet the QC / T658-2000 standard requirements: 38 ± 1 ℃, the humidity is 68 ± 5% RH, continuous operation: the temperature is 30 ℃, the car idling state, the vehicle maximum heat of 25KW, the maximum relative humidity of 90 ± 5% RH, running for 1 hour.

Test the environment temperature and humidity, can track the load changes, can be set in the humidity control temperature stability rate test:

From room temperature to +60 ℃ maximum temperature: not more than 3h

From room temperature to -40 ℃ the longest time: not more than 3h

Process Profile

Structure technology

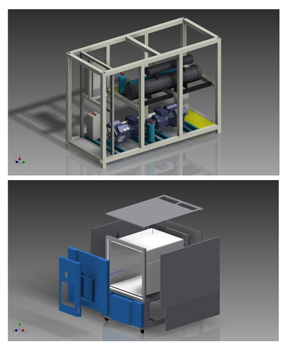

1.Company hardware equipment

Imports of German laser laser machine 1;

Title of the AMADA AIRS-255NT punching and a Taiwan;

Germany for all types of carbon dioxide welding machine and argon welding machine more than 10 Autodrsk inventor 3D graphics software, 3D sheet metal demolition and design of virtual assembly.

2.Shell made of high quality galvanized steel, electrostatic powder coating to be paint;

3.The inner box is made of imported SUS # 304 stainless steel, with full welding process to prevent leakage and penetration of high temperature and high humidity air inside the box; inner liner fillet design of inner box can better discharge condensate of side wall.

2.Shell made of high quality galvanized steel, electrostatic powder coating to be paint;

3.The inner box is made of imported SUS # 304 stainless steel, with full welding process to prevent leakage and penetration of high temperature and high humidity air inside the box; inner liner fillet design of inner box can better discharge condensate of side wall.

Refrigeration series of technology

1.standardization

1.1 High-quality steel pipe and welding process standardization; according to the standard tube layout to ensure stable and reliable model system;

1.2 Imports of Italian imports of pipe bending machine the whole bend, a significant reduction in solder joints and welding generated when the pipe oxide, improve system reliability!

2.Pipeline shock and support

2.1 The United States and Tyco on the support of the cooling copper pipe has strict requirements, taking into account the pipeline shock conditions in the cooling pipe to increase the arc and bending the use of special nylon clip fixed way to avoid the circular vibration and temperature changes caused by Pipe deformation and leakage, improve the reliability of the entire refrigeration system.

2.2 No oxidation welding process

As we all know, the cleanliness of the refrigeration system is directly related to the efficiency of the refrigeration system and operating life; the United States and Tyco welding operation using standardized to avoid a large number of pipe oxide pollution when welding!

Control circuit technology

1. Power distribution layout According to the technical department of the distribution assembly plans to install electrical components used internationally renowned brands: Omron, Schneider, Germany phoenix terminals, line code clearly marked.

Selection of the old domestic brand, (Zhujiang cable) to ensure that the quality of the wire; control line minimum 0.75 square RV soft copper wire, all the major load such as motor compressors are based on EC trunking safety current standard trapping trail selection!

Compressor cable box cable mouth with sealant processing, to prevent frosting junction box terminal short circuit.

All terminal screws are connected to the standard fixed torque, to ensure reliable fastening to prevent loose ignition and other hidden dangers!

Refrigeration Technology

3D refrigeration system management drawing

Variable Frequency Control Technology of Refrigeration System

In the frequency conversion refrigeration system, even if the power frequency 50HZ is fixed, can change the

frequency through the frequency changer, thus adjusts the compression rotational speed, causes the cold quantity

continuously to change, guarantees the compressor movement load in the test box the actual load to match (namely

test body temperature Increase, the compressor frequency to rise, improve the cooling capacity, on the contrary, the

compressor frequency to reduce and reduce the cooling capacity) greatly saves the unnecessary loss of operation to achieve energy-saving purposes. In the beginning of the test chamber can also run by increasing the frequency of the compressor to improve the capacity of the cooling system to achieve the purpose of rapid cooling.

The chamber adopts frequency conversion refrigeration system, which can precisely control the temperature of the box body, make the temperature of the box body constant, the temperature fluctuation is small, and the suction and discharge pressure of the refrigeration system is stable and the compressor runs stably and reliably. Electronic expansion flow servo.

Refrigeration system technology Other energy - saving technologies

A) The use of PID + PWM principle VRF technology (electronic expansion valve according to the thermal conditions of flow control)

Low-temperature working state, the heater does not participate in the work, through the PID + PWM regulation of the cooling (cooling capacity of the air flow control system); low-temperature working conditions, the use of the principle of PID PID VRF technology (refrigerant flow control) Flow rate and flow direction of the cooling pipe, cold side of the pipeline, heat the next three-way flow pipe to adjust to achieve the work of the temperature is automatically constant, this method in low temperature conditions, the studio can automatically achieve a constant temperature, Low temperature conditions, can achieve a 30% reduction in energy consumption. The technology is based on Danfoss ETS system electronic expansion valve, can be applied to different cooling capacity requirements of the cooling adjustment, both at different cooling rate requirements, to achieve the compressor cooling capacity adjustment.

B) the size of two sets of compressor design technology, according to load conditions automatically start and stop (large series is designed)

The refrigeration unit is equipped with a set of semi-hermetic compressors composed of binary cascade refrigeration system plus a full-density single-stage refrigeration system. Configure the mother; according to the load conditions inside the box and the cooling rate of intelligence to open the different compressor groups, so that the cooling capacity of the box and the compressor output power to achieve the best match, in order to achieve the best operating conditions in the compressor section circle to Extend the service life of the compressor. More importantly, a large set of traditional design compared to the energy-saving effect is very obvious, you can achieve more than 30% of the temperature control. With VRF technology)

Automobile integrated environmental experiment warehouse

Automobile integrated environmental experiment warehouse

Comprehensive technical parameters of automobile integrated environment

Comprehensive technical parameters of automobile integrated environment

Process Profile

Process Profile