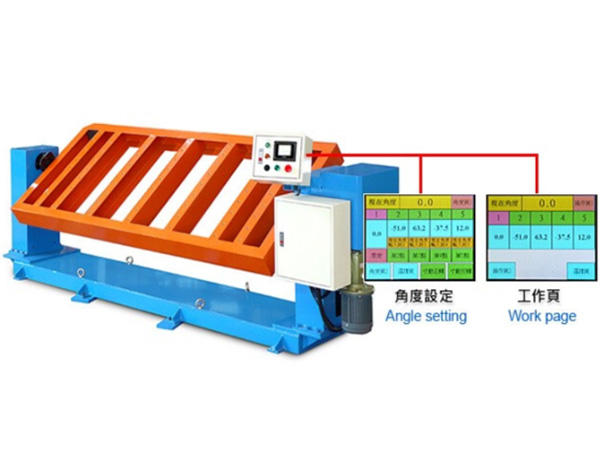

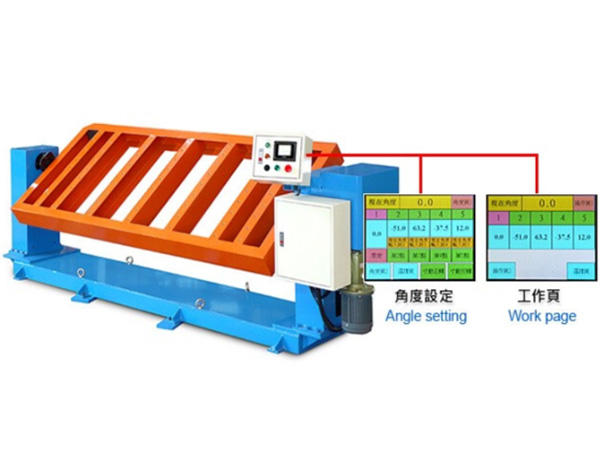

Battery pack reversing testing machine

Battery pack reversing testing machine

| name | Flip test machine | |

| Specifications Model | MBS—FZ31467 | |

| Flip plate size | Width W2000 * long KL2000 * thick D100mm | |

| Equipment size | Wide W4000 * long L4000 * high Hl600mm | |

| control method | Remote control or separate experimental air control | |

| Structure part | control box | The control box is separated from the test chamber to ensure the safety of the test personnel |

| Fixture | Set by 8 large bolts | |

| Product handling | Lifting forklift or driving | |

| Security | Before the operation of the equipment, please check the product fixed, the operation as far as possible away from the equipment, the control system with parameter settings, the device can be automatically according to the parameters of the whole process, please confirm the device stops and then close the control box with emergency button | |

| device installation | Need to firmly flat concrete foundation | |

| Technical Parameters | Flip direction | X vertical and Y levels |

| Rollover time | 0-999H, time and status can be adjusted according to the test requirements | |

| Flip speed | l° -10 ° / s adjustable | |

| Insurance buckle | In the turntable drive system cover, diameter 50mm (test stop automatically lock) | |

| Drive mode | electric | |

| Meet the test standards |

GB / T 31467.3-2015 Lithium-ion power for electric vehicles - Storage and systems - Part 3: Safety requirements and testing 7.4 flip 7.4.1 The test object is a battery pack or system. 7.4.2 The test object is rotated 360 ° around the z axis at 6 ° / s and then rotated in increments of 90 ° for 1 h at 90 ° increments and rotated by 360 ° stop. Observed for 2 h. 7.4.3 The test object is rotated 360 ° around the y-axis at 6 ° / s and then rotated in 90 ° increments, maintained at 30 ° increments by 30 ° stop. Observed for 2 h. 7.4.4 requirements: battery pack or system without leakage, shell rupture, fire or explosion and other phenomena, and to maintain a reliable connection, well-structured, test |

|